Our new website had been built, here you can see the completed installed flour mill plant in Zambia, Ethopia, New Zealand, Algeria etc, they have already begun to profit for our customers! YOU ARE WELCOME TO VISIT!

The use of small scale flour mill machinery dates again to several years even though now there was a considerable amendment within the sorts and sizes of machines. in advance flour used to be ground in the traditional manner the use of hand gear which involved time and effort. As time complicated, the obsolete manners gave way to extra sophisticated machines.

There are several types of small scale flour mill machinery used for grinding flour such as the ball mill, grist mill and so forth. These kinds of mills are utilised for grinding wheat flour and different cereals for both family and industrial purposes.

Purchase Notice

As there are a selection of small scale flour mill machineries available, you will need to make a selection machines that support on your requirement. one of the most essential points to imagine prior to choosing a flour mill include:

Size&Design

As there are rather numerous small scale flour mill machineries available, you will need to make a selection machines that suit your kitchen requirements. With an array of colors available both within the on-line and offline retail outlets, opting for an apt flour mill might not be a difficult task.

Amount:

These machines can also be selected in step with the scale and quantity of flour required. One of the machines are rather huge whereas a few are appropriate for grinding flour in small amounts.

Types:

There are mainly two forms of grinding turbines mainly electric and handbook turbines. The manual turbines are appropriate for grinding flour for a small circle of relatives the place as electrical turbines grind flour in huge amounts and are suitable for larger households.

Prices:

There are a variety of machines to be had within the online shops at a number of costs. It’s pertinent to select a flour mill that fits your need and funds concurrently.

Useage:

One of the basic reasons for the larger use of small scale flour mill machineries is that it helps to grind wholesome and wholesome wheat flour. Among the readymade wheat flour accommodates preservatives and chemical compounds which might be damaging to well being. Grinding wheat flour using these machines is helping to hold its dietary worth and goodness.

Grinding wheat flour using these machines is helping to avoid wasting time and effort so most people prefer to make use of such systems at home. The electrical flour mill gadget is manufactured with complex technological features together with stainless steel blades, ability to adjust the speed of the grinder and so on. Though these gadgets are fairly expensive, it is value the cost and options a just right investment.

In addition to grinding wheat flour, those machines are also used to grind spices and nuts. One of the crucial grinding machines like the ball mill and the grist mill are used for enormous scale grinding of wheat flour.

The ball mill is a simple grinder that involves an elevated cylinder with stone and it is used for generating wheat flour in huge quantities. The grist mill is an electrical grinding machine that helps to grind flour briefly and in large quantities. These devices can also be got from the flour mill system manufactures listed in the trade portals.

If you have no idea of whatever you want, you should try seeking for assistance from anyone that has vast knowledge on the wheat grinding machines. When purchasing wheat-grinding machines, you should know that the hand cranked wheat machines are usually less noisy and less expensive compared to the electric grinders. However, you should know that the hand-cranked grinders would require you to use some extra strength for you to operate them. When shopping for wheat grinders, you should try looking for the grinders that are made of high quality parts. Most of these parts are usually made from stainless steel; therefore, you can always tell the difference from the rest.

If you have no idea of whatever you want, you should try seeking for assistance from anyone that has vast knowledge on the wheat grinding machines. When purchasing wheat-grinding machines, you should know that the hand cranked wheat machines are usually less noisy and less expensive compared to the electric grinders. However, you should know that the hand-cranked grinders would require you to use some extra strength for you to operate them. When shopping for wheat grinders, you should try looking for the grinders that are made of high quality parts. Most of these parts are usually made from stainless steel; therefore, you can always tell the difference from the rest. The wheat is then passed through an aspirator which is a device like a vacuum cleaner. The aspirator will suck up any foreign materials that are lighter than the wheat. The wheat is then washed in warm water and air dried. The next step involved in wheat flour production process is conditioning. In this process, the wheat is soaked in cold water for about 3 to 4 days or at a temperature of 46 degrees Celsius.

The wheat is then passed through an aspirator which is a device like a vacuum cleaner. The aspirator will suck up any foreign materials that are lighter than the wheat. The wheat is then washed in warm water and air dried. The next step involved in wheat flour production process is conditioning. In this process, the wheat is soaked in cold water for about 3 to 4 days or at a temperature of 46 degrees Celsius. Wheat flour processing involves various stages. Before the wheat is processed, it must first have to be cleaned. Magnets are used to remove any metallic object, stones, and any other foreign materials that can be attracted by a magnet. Dust and chuffs in the wheat is removed by passing the wheat through air currents. There is an advanced color sorter being used today that separates impurities from the wheat by difference in color. This therefore reduces the product’s overall waste and improves the quality of flour.

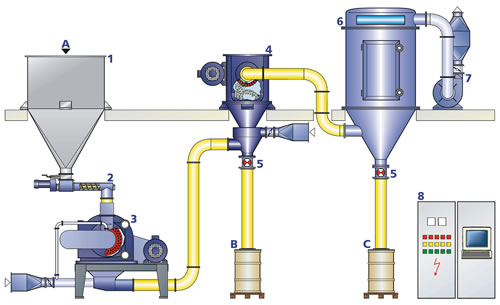

Wheat flour processing involves various stages. Before the wheat is processed, it must first have to be cleaned. Magnets are used to remove any metallic object, stones, and any other foreign materials that can be attracted by a magnet. Dust and chuffs in the wheat is removed by passing the wheat through air currents. There is an advanced color sorter being used today that separates impurities from the wheat by difference in color. This therefore reduces the product’s overall waste and improves the quality of flour. Wheat flour making machine uses a pneumatic roller mill and a high square sifter in making wheat flour. It also has an advanced impulse dust collector which ensures that the workshop is kept clean. This machine is easy to assemble and use. In addition to that, limits the loss of wheat flour during the milling process as to prevent contamination to the outside air. The final products from this machine have al grades suitable for animal feeds and also fine flour for human consumption.

Wheat flour making machine uses a pneumatic roller mill and a high square sifter in making wheat flour. It also has an advanced impulse dust collector which ensures that the workshop is kept clean. This machine is easy to assemble and use. In addition to that, limits the loss of wheat flour during the milling process as to prevent contamination to the outside air. The final products from this machine have al grades suitable for animal feeds and also fine flour for human consumption. This machine has great benefits. It has a high yield in dergerming of wheat. This is because of the newly improved chamber that contributes to higher yield. The machine also has a lower operation and installation costs. It also consumes less power. Therefore, you do not have to worry about electricity bills when you have it. Its compact design lowers the need of low space. It also produces products of high quality and has a high milling rate.

This machine has great benefits. It has a high yield in dergerming of wheat. This is because of the newly improved chamber that contributes to higher yield. The machine also has a lower operation and installation costs. It also consumes less power. Therefore, you do not have to worry about electricity bills when you have it. Its compact design lowers the need of low space. It also produces products of high quality and has a high milling rate. The idea of setting up a wheat flour mill can either be electrically or manually planned. Additionally, it is not a difficult act to do simply because it will provide you with a chance of grinding your own wheat to cater for your family’s needs and requirements. For you to come up with the type of mill for you whether manual or electric, you are highly advised to out all your needs, requirements and preferences into consideration first. This will in turn help you in making the right decision. Consider the purpose that you intend to use the flour mill as well and you will come up with a perfect choice. Keep reading to learn more.

The idea of setting up a wheat flour mill can either be electrically or manually planned. Additionally, it is not a difficult act to do simply because it will provide you with a chance of grinding your own wheat to cater for your family’s needs and requirements. For you to come up with the type of mill for you whether manual or electric, you are highly advised to out all your needs, requirements and preferences into consideration first. This will in turn help you in making the right decision. Consider the purpose that you intend to use the flour mill as well and you will come up with a perfect choice. Keep reading to learn more. When setting up a wheat flour mill, it is important to consider its condition first. For instance, you ought to determine whether you want the mill to have a clamping mechanism or one which requires some screwing. Determine the type of surface you will be using it and this in turn will help you in choosing the right mill for you.

When setting up a wheat flour mill, it is important to consider its condition first. For instance, you ought to determine whether you want the mill to have a clamping mechanism or one which requires some screwing. Determine the type of surface you will be using it and this in turn will help you in choosing the right mill for you. You will need a wheat flour machine and dry wheat to make wheat flour. The wheat can be either electric cranked or hand cranked depending on the type of machine you won. Basically, there are three types of flour depending on the type of the wheat used to make the flour. Wheat is divided into three parts namely the endosperm, the germ and the bran. The endosperm is the area that carries a lot of proteins and starch, the germ is rich in vitamins and proteins while the bran contains the fiber. If you want white flour, you will use the endosperm only while whole meal flour is made from the three parts. It is important to sift through the wheat to remove any remaining particles before using it. Note that there are different types of wheat based on protein content and other factors. All purpose wheat, for instance, is low in protein and best used to bake cakes and bread. On the other hand, bread flour has high protein content and can be sued to make yeast break.

You will need a wheat flour machine and dry wheat to make wheat flour. The wheat can be either electric cranked or hand cranked depending on the type of machine you won. Basically, there are three types of flour depending on the type of the wheat used to make the flour. Wheat is divided into three parts namely the endosperm, the germ and the bran. The endosperm is the area that carries a lot of proteins and starch, the germ is rich in vitamins and proteins while the bran contains the fiber. If you want white flour, you will use the endosperm only while whole meal flour is made from the three parts. It is important to sift through the wheat to remove any remaining particles before using it. Note that there are different types of wheat based on protein content and other factors. All purpose wheat, for instance, is low in protein and best used to bake cakes and bread. On the other hand, bread flour has high protein content and can be sued to make yeast break.